Service Door Models

Standard Duty

The R&S Standard Duty door is an economical yet reliable service door.

Heavy Duty

The R&S Heavy Service Duty door provides high security and durability offering years of maintenance free performance.

Climate Guard

Climate control is provided by the combination of a flat slat curtain, hood baffle, guide weatherstripping and astragal.

Thermal Guard

An effective thermal barrier is created by the combination of 22 gage (min.) steel flat faced slats, 3/4” polyurethane foam, and 24 gage steel back slats.

Type 30 Slat

Standard curved slat for use on all service doors where strength and durability are a consideration. Available in 24, 22, 20, or 18 gage galvanized steel. Also for use on all fire doors.

Type 25 Slat

Standard flat slat for use on all service doors where environmental conditions are a consideration. Available in 24, 22, 20 or 18 gage galvanized steel. Also

for use on all fire doors, especially those requiring gasketing.

Type 20 Slat

Optional curved slat for use on Service doors to 16’ wide. Available in 22 or 20 gage galvanized steel. Also for use in fire doors to 15’ wide.

Type 17 Slat

Optional flat slat for use on service doors to 16’ wide. Available in 22 or 20

gage galvanized steel or 22 gage stainless steel. Also optional on fire doors to 15’ wide. Standard on counter fire doors and counter doors.

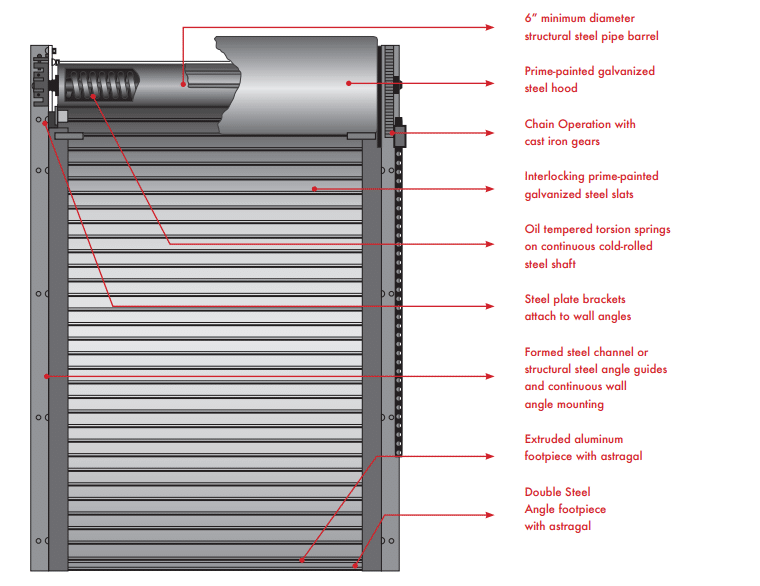

Specifications

- SD,D,W,I – Service doors are designed to withstand a minimum 20 PSF

windload.

- SD – One year or 12,500 cycles.

- D,W,I – Two years or 20,000 cycles

- SD,D,W,I – Chain hoist is standard; push-up (small sizes), awning crank,

crank box or motor operation are optional.

- SD,D,W,I – Galvanized steel slats with baked on gray polyester primer

standard. Tan or uncoated galvanized finish available upon request. - SD – 24 gage slats with stamped steel endlocks.

- D,W – 22,20,18 gage slats, as required to meet windload, with stamped

steel endlocks. Windlocks are riveted to slats when required to meet

windload. - I – Same construction as D and W models with the addition of ¾” laid in

place polyurethane or polystyrene foam concealed by 24 gage backslat

- SD,D,W,I – Extruded aluminum footpiece with astragal standard up to 16’

wide - D,W,I – Double steel angle footpiece with astragal standard over 16’.

Painted with rust inhibiting black primer.

- SD – Steel channels bolted to structural steel wall angles. Painted with rust

inhibiting black primer. - D,W,I – Structural steel angles bolted to structural steel wall angles.

Windlock bars are installed when windlocks are required to meet windload.

Painted with rust inhibiting black primer. - W,I – Climate and Thermal-Guard models also include vinyl guide

weatherstripping against the flat-faced side of the slats.

- SD,D,W,I – Steel plate brackets are bolted to wall angles to support curtain

and barrel, and provide mounting for hood. Painted with rust inhibiting

black primer.

- SD,D,W,I – Steel plate brackets are bolted to wall angles to support curtain

and barrel, and provide mounting for hood. Painted with rust inhibiting

black primer.

- SD,D,W,I – minimum 6” diameter steel pipe houses torsion spring assembly

and supports curtain. Torsion springs are mounted on a continuous cold

rolled steel shaft, adjustable by a tension wheel on the outside of bracket.

- SD,D,W,I – Formed 24 gage galvanized steel sheet, with baked on gray

polyester primer reinforced with top and bottom flanges to limit deflection.

Intermediate support is provided when required. - W,I – Internal rubber baffle hangs against curtain to reduce air infiltration

• SD,D,W,I – Chain lock with chain operation and slidebolt locks with push-up

or crank operation standard.

Options

Curtain designs to withstand windloads exceeding 20 PSF.

Designs to provide up to 150,000 operating cycles or maximum possible design.

3/64” diameter holes on 5/64” staggered centers in type 25 slats provide

30% open area for ventilation and visibility throughout the curtain.

Single or multiple 3” wide cut-outs, open for ventilation or covered with

acrylic.

Powder Coating available on all exposed surfaces.

Hot dip Galvanizing available on footpiece, guides and brackets.

Partial grille curtain connecting slats above and below.

For door openings on a slope.

Key or finger-throw cylinder installed on footpiece for easy secure locking.

3’-0” x 7’-0” x 1-3/4” thick hollow metal gray primed (black optional) door in

a steel frame for access through the curtain when closed; frame is hinged to

guide and swings clear to allow use of entire door opening when curtain is

raised.

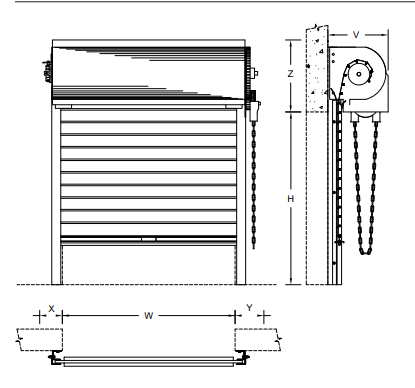

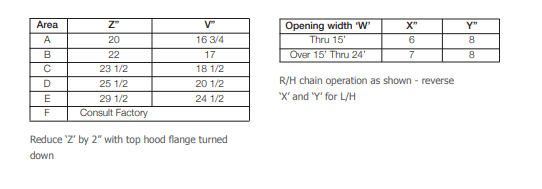

Mounting Details

Standard Clearance Requirements

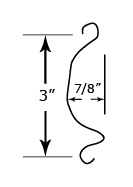

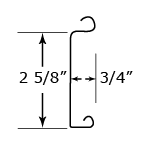

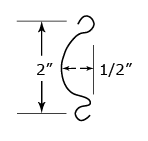

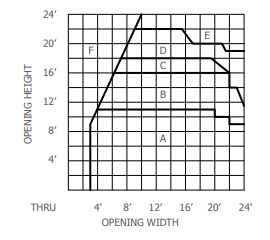

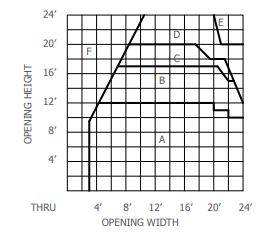

Large Flat (#25)

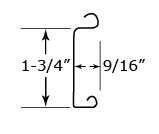

Large Curve (#30)